— Our Resources

Crane Lifts

The use of cranes to lift and set equipments is probably the most preferred option by any project team. This is of course after due consideration has been given to crane access, assembly time, suitability of crane pads, obstructions during lifting among other things.

All critical lifts require a lift plan . Critical does not necessary mean the load is just heavy . A column weighing 105T being lifted at a radius of 7. 5m is as critical as a stack piece weighing 16T being lifted at a radius of 27m. Therefore , the parameters lift weight and lift radius must both be considered in classifying a lift as critical. Lifts using more than one crane are usually classified as critical.

The picture shown at right is a 260T generator being lifted to the runway beams by a 450T Demag CC2400 crane in superlift configuration. The lift plan and procedure was done by MOFS Engineering.

Cranemats were used to provide better bearing support for the crane. This solution saved the client a day compared to the original scheme of jacking the generator up in stages from the top of the runway.

This shows that even with an already accepted method, MOFS has proven to be versatile in adapting to what is readily available at site providing value service to all our clients.

Jack & Roll

The JACK & ROLL way of setting equipments on top of foundation bolts for final installation is major part of MOFS installation philosophies.

Shown is MOFS 800T Hydraulic Gantry supported on 170 ft of Heavy Duty Runway being used to move the 260T generator to its foundation. The lift systems prove to be a very versatile equipment specially useful when access to a crane is non-existent or when the weight is too heavy that the use of a corresponding heavy lift crane is not economically practical.

In most cases , the load has to supported on temporary lift frames to enable adjustments of the link lengths used in conjunction with the maximum safe stroke that the cylinders are allowed based on computed loads. MOFS Gantry Systems come complete with runways, hydraulic push cylinders, lift links controlled centrally from a single station ensuring a safe and timely erection.

Close coordination with the client team is required specially on civil requirements such as temporary foundations , level surveys, ground preparation and the like.

Land Transport

MOFS has a wide array of choices for transporting within a project site or from any designated pick-up point to any destination. A careful study of the route, height limitations, bridge ratings, grades and road conditions are all collectively considered in deciding the best type of trailer/prime mover combination.

Shown above is a 43T HRSG Side Panel being moved on an 8-line Goldhofer Trailer up an 8% grade.

Our transport equipments compliment each other. Most project sites in the Philippines are isolated. Careful planning is a must for the project cargo to reach the site safely and on time. This requires control over the land and sea routes.

MOFS Engineering provides the technical support to enable proper planning and execution in the transport of over size cargoes.

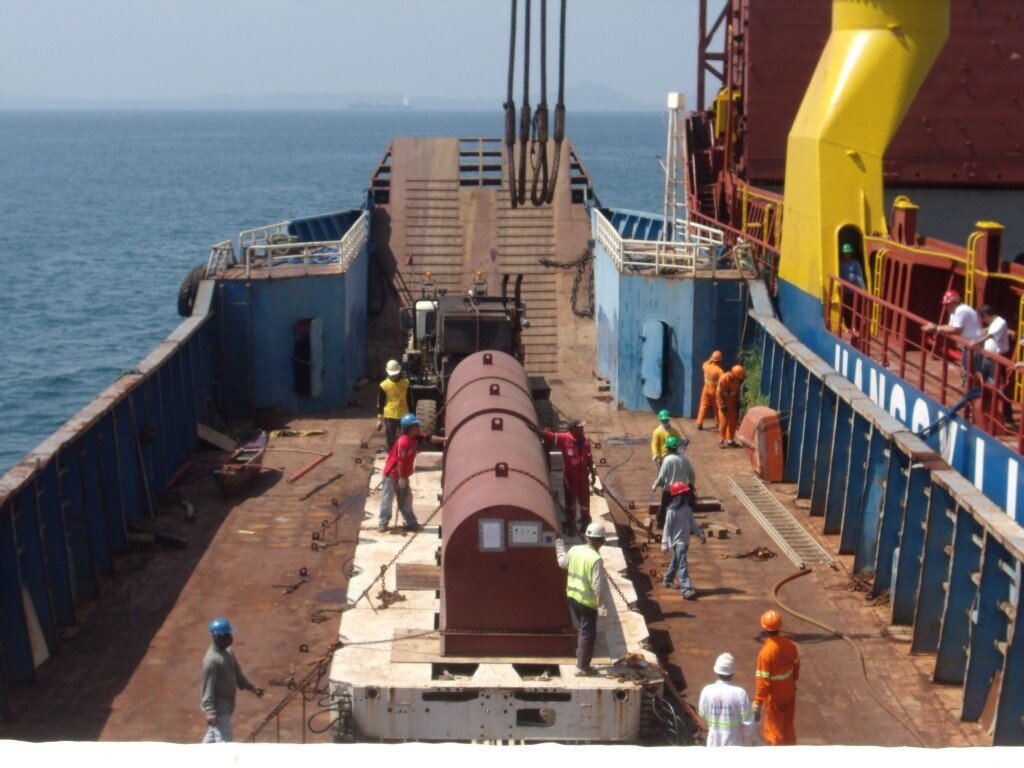

LCT Chartering

One advantage MOFS has is ownership of three 1200 DWT LCT's. Many of the project sites in the Philippines are not accessible by land. Being able to receive the cargo in protected waters then sail to the designated site and roll or lift the cargo off means more control over arrival of equipments on site.

With land and sea covered, our client's cargo gets to it's destination safely and on schedule.

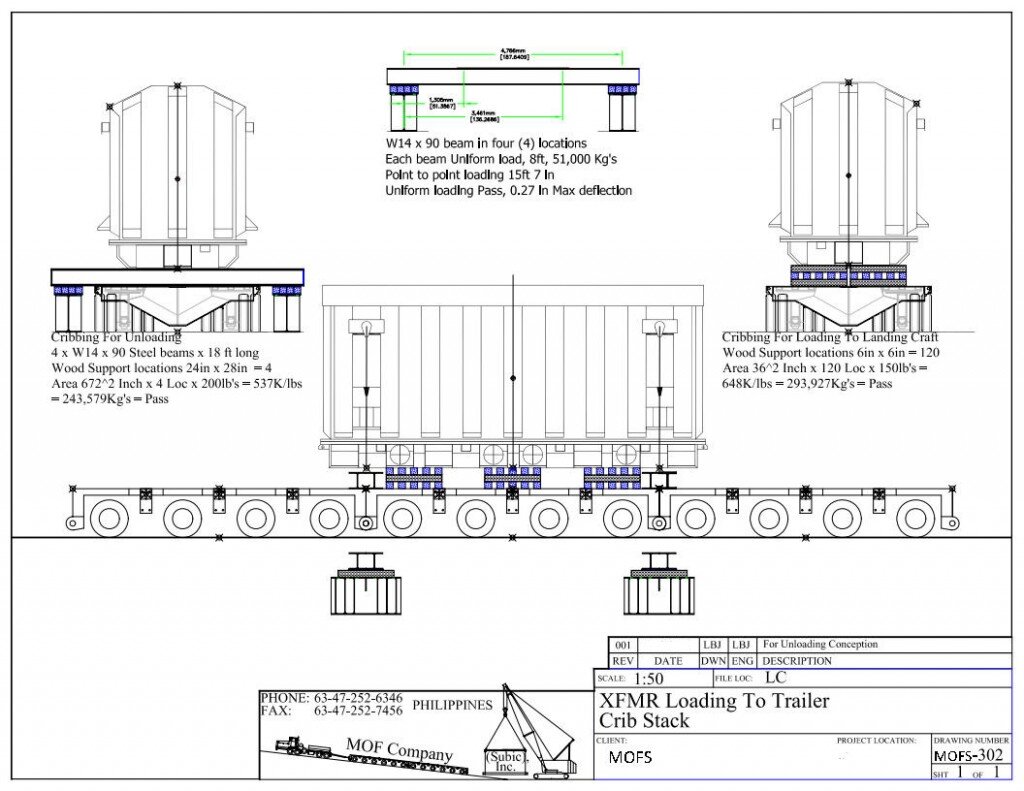

Engineering investigation is often necessary for special loads such as the one shown at right. Temporary supports were needed to transport the 260T Generator shown. Finite structural models of the deck and the structure underneath were run and the analysis results used to confirm the adequacy of the loaded points.

Likewise, sea stability was ensured by calculating the required ballast water to trim the LCT for the voyage. Based on the hydrostatic curves for the LCT, an analysis was made as to the stability of the vessel against list, roll and yaw.

Tech Services

From concept to execution, the requirements and drawings undergo an approval process to ensure that costly errors and delays are avoided.

We use Computer Aided Design Systems ( AUTOCAD and STAAD ) combined with operations experience to give you better enginering services :

Heavy lift and erection plans using cranes, hydraulic jacks, strand jacks, hydraulic platform trailers & LCT's.

Supporting stability calculations

Structural steel, ducting design calculations

Structural detail engineering

cutting lists and material estimates

Piping detail engineering

Learn more about our Heavy Lift Engineering services.

Specific information about your requirements will be supplied upon request.